PROJECTEURS LED ATEX POUR ZONES DANGEREUSES

Découvrez notre gamme de projecteurs LED ATEX pour travailler en toute sécurité dans les milieux les plus dangereux et difficiles. Certains de nos produits d’éclairage LED bénéficient des certifications ATEX pour le travail en zones explosives. Découvrez l’ensemble de nos produits d’éclairage antidéflagrant LED de notre gamme ATEX.

Solutions sur mesure

Service après-vente spécialisé

Devis rapide

Une équipe d’experts

Pourquoi choisir un projecteur atex led pour zones dangereuses ?

Les projecteurs ATEX sont essentiels pour garantir la sécurité et l’efficacité dans les zones dangereuses. Ces zones, souvent présentes dans les industries pétrolières, chimiques, plateformes off-shores et gazières, sont exposées à des risques élevés d’explosions en raison de la présence de gaz inflammables, de vapeurs ou de poussières.

Qu’est-ce qu’un projecteur led certifié ATEX ?

Les projecteurs conformes à la norme ATEX (Atmosphères Explosibles) sont conçus pour fonctionner en toute sécurité dans des environnements présentant des hauts risques d’explosion. Les projecteurs ATEX pour zones dangereuses sont fabriqués avec des matériaux résistants aux chocs et à la corrosion, et sont dotés de technologies avancées pour prévenir toute étincelle ou surchauffe. Ils offrent une excellente qualité d’éclairage, assurant ainsi une visibilité optimale pour les travailleurs, ce qui est crucial pour la prévention des accidents et l’amélioration de la productivité.

Choisir le bon projecteur ATEX pour une zone dangereuse nécessite une évaluation précise des conditions environnementales et des besoins spécifiques de l’application.

Les différentes zones en atmosphères explosives

Les zones de travail explosives sont classées selon leur niveau de dangerosité et sont réglementées par la directive ATEX 99/92/CE. Il est ainsi nécessaire d’évaluer les risques d’explosion pour faire une classification claire de votre environnement ATEX.

Les zones 0 à 2, sont les zones présentant un risque inflammable dû à la présence de gaz. Les zones 20 à 22, sont les zones présentant un risque dû à la présence de poussières explosives.

Pour les milieux gazeux :

- Zone 0 = présence permanente

- Zone 1 = présence occasionnelle

- Zone 2 = présence rare

Pour les milieux poussiéreux :

- Zone 20 = présence permanente

- Zone 21 = présence occasionnelle

- Zone 22 = présence rare

Quel est le rôle d’un éclairage antidéflagrant ou anti-explosion pour votre chantier ?

Les éclairages de chantiers ATEX, également appelés luminaire anti-déflagrant ou eclairage explosif jouent un rôle essentiel sur les chantiers en environnements dangereux présentant un risque probable ou important d’explosion.

On parle ainsi de lampe ATEX ou projecteur led atex pour les éclairages anticipant ces risques de déflagrations.

Quels sont les éléments déclenchant un départ de feu ou une explosion sur un chantier en zone dangereuse ?

Le départ d’un feu ou d’une explosion est dû à trois éléments se réunissant simultanément que l’on appelle le triangle de feu :

- La présence d’une source d’ignition

- La présence d’un combustible (matériaux brûlant au contact d’une flamme type papier, bois, essence ou encore gaz)

- La présence d’un comburant (l’air nécessaire pour alimenter un feu, généralement de l’oxygène ou des nitrates)

Les sources d’ignitions en zone à risque explosif sont multiples, elles peuvent être dû à :

- Une flamme nue ou un solide incandescent

- Un point chaud provenant d’une friction ou d’un effet joule (dégagement de chaleur provoqué par le passage d’un courant électrique dans un matériau conducteur lui opposant une résistance)

- Un effet électrostatique ou une étincelle électrique

- La compression adiabatique d’un gaz présent sur le chantier (montée en température excessive du gaz)

Comment prévenir ce risque ?

Utiliser des projecteurs antidéflagrants est une bonne façon de réduire les risques d’explosions ou d’en atténuer les effets en éliminant une source d’inflammation potentielle. Les éclairages utilisent de l’électricité pour fonctionner, et peuvent donc créer des effets électrostatiques ou des étincelles. Ainsi, utiliser une lampe atex limite drastiquement le risque de départ de feu ou d’explosion dans une zone dangereuse.

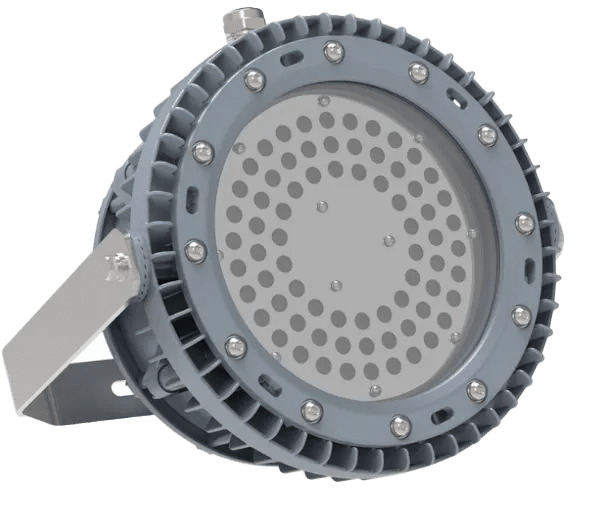

Notre gamme de projecteurs led pour vos installations en atmosphère explosive

Grâce à leur conception robuste et leur certification rigoureuse, ces projecteurs peuvent fonctionner de manière fiable sous des conditions extrêmes. Ils offrent également une luminosité optimale, permettant aux travailleurs d’effectuer leurs tâches en toute sécurité. L’utilisation de projecteurs ATEX est donc indispensable pour se conformer aux réglementations de sécurité et pour protéger à la fois le personnel et les installations.

Parmi notre gamme, il est possible de retrouver à la fois des éclairages filaires, mais également des éclairages rechargeables, pour les chantiers où il n’est pas possible d’accéder au courant du secteur 230V.

Nos projecteurs mobiles ATEX : leur puissance s’étende de 7 346 Lumens à 17 000 Lumens pour les plus puissants. Ils conviennent à des usages en zones 1/21 et en zones 2/22, ainsi, ils sont généralement utilisés par les plateformes pétrolières, les usines pétrochimiques ou sur des chantiers industriels de tous types. Découvrez notamment notre projecteur ATEX 150W, le plus puissant de notre gamme.

Nos projecteurs rechargeables ATEX : nous proposons deux projecteurs de chantier ATEX sur batterie, le SAFATEX® TITAN EX1400R, développant une puissance de 1 400 Lumens pendant 10H et utilisable en zones 1/21, ainsi que le projecteur rechargeable atex RALS 9455, utilisable pour sa part en zones 0/20 et développant une puissance de 1 600 Lumens pendant 5 à 10 heures. Ces derniers sont pour leur part particulièrement utilisés dans des carrières ou des mines (charbon, métaux…), pour le traitement des eaux usées ou encore pour les espaces de stockages (gaz, solvants…).

En intégrant des projecteurs ATEX dans vos installations, vous faites un pas important vers la réduction des risques et la création d’un environnement de travail plus sûr. Pour plus d’informations sur les projecteurs ATEX adaptés aux zones dangereuses, n’hésitez pas à contacter nos spécialistes qui sauront vous guider dans le choix des équipements les plus appropriés pour vos besoins spécifiques.